Lean Manufacturing Fundamentals - 5 principles for creating superior value

Unpacking the five key principles of the Lean Manufacturing methodology.

As UK manufacturers strive to cope with a range of global challenges, many are turning to the Lean methodology, pioneered by Toyota, that has become the global standard for operational excellence. Unfortunately, Lean is widely misunderstood, and even though Lean techniques are familiar in most factories, deployment is typically superficial, leading to disappointing results.

Companies that have practiced Lean as the comprehensive system it was designed to be, however, have earned an impressive track record of breakthrough results such as lead times cut to a fraction of what they were, capacity doubled with existing resources, or dramatic improvements in customer satisfaction and market share.

What is lean manufacturing?

Lean manufacturing is a customer-focused production approach that maximises efficiency, minimises waste, and emphasises continuous improvement. It aims to streamline workflows, reduce non-value-added activities, and optimise resources for cost-effective, high-quality product delivery.

The History of Lean manufacturing

The set of practices now known as Lean was borne out of dire necessity. Japan had been devastated by World War 2, and its manufacturing sector needed to become viable as quickly as possible with very few resources. The Toyota Production System, which eventually evolved into Lean, was at the outset a way of doing more with less.

The rest is history. The thinking behind the Toyota Production System helped Japan execute one of the most stunning turnarounds in manufacturing history and established Toyota as a global icon. The system, later called Lean, has become the global standard for operational excellence in virtually every sector.

While circumstances in the UK aren’t as desperate as those Japanese manufacturers faced in the early 1950s, they are, nonetheless, daunting. Growth since the financial crisis of 2008 has been either minimal or negative, and UK manufacturers are facing a challenging environment of unpredictable markets, global instability, and the pending retirement of millions of skilled workers with little prospect of replacing them. Finally, there are concerns about the pressures to transition to what is being called Industry 4.0.

Lean tools - kanban, 5S, jidoka, heijunka, takt time, single-minute exchange of dies (SMED), the 5 whys – are nothing new for most companies and are widely used in efforts to improve efficiency and agility. However, the basic thinking behind Lean is still widely misunderstood, and consequently, few companies have been able to achieve the game-changing results demonstrated by world Lean leaders like Toyota, Danaher, and Bosch.

These world leaders have succeeded because they have the management and information structures in place to support ongoing Lean activity in all functional areas and levels of hierarchy. This structure not only supports the changes in corporate priorities that Lean demands, but also calls for the Lean definition of success to be applied in the day-to-day operations of the company.

Lean principles are surprisingly relevant in the age of Industry 4.0. Lean companies are finding, for example, that the powerful combination of artificial intelligence (AI) and Internet of Things (IoT) can help improve Lean workflows in automated environments and create a better partnership between humans and machines.

How Lean Creates Superior Value?

In his later years, Taiichi Ohno, the acknowledged innovator and champion of the Toyota Production System, was frequently asked to summarise what this revolutionary method was all about. This is what he reportedly said:

All we are doing is looking at the timeline, from the moment the customer gives us an order to the point when we collect the cash. And we are reducing the timeline by reducing the non-value adding wastes.

This simple quote sounds on the surface like a statement of the obvious, but it suggests the entire framework for Lean, including all of its tools. Furthermore, it reflects thinking that was revolutionary – so much so, in fact, that many have difficulty grasping it even today.

Embedded in Ohno’s words are five basic principles:

- The Lean Value Stream

- Eradication of Waste

- Flow Regulated by Demand

- First-Time Quality

- Continuous Improvement

These principles are explained below. To help visualise them, imagine that a hypothetical manufacturer, ABC Manufacturing, has a line with four processes:

To understand Lean, we need to understand how the workpiece moves through each process in order to become a finished product that the customer is willing to pay for.

Principle #1: The Lean Value Stream

A conceptual representation of the entire sequence of actions and expenditures that culminate in a product or service of value to customers.

Lean environments are managed by looking at the big picture of production, that is all the steps that are taken from the time of order to the time of delivery to the customer. This is the end-to-end timeline that Ohno refers to above. We call this the value stream because the characteristics of the product that make it worth paying for are created in the series of steps on the production line, each step contributing to the value of the final product. There may be different functional groups involved – stamping, machining, welding, assembly, for example – but the performance metrics used are all based on the end-to-end performance of the entire value stream.

Value stream awareness on a production line helps people in all these functional areas work together to improve operations in order to deliver better value to the customer. A useful way of looking at this is that the workpiece is a proxy for the customer who will eventually own the product – if we treat the workpiece well, we are treating the customer well.

Reducing the timeline, as Ohno suggests, helps us get the product to the customer sooner, but equally important, it forces us to eliminate unnecessary steps, ultimately lowering the cost of making the product.

The biggest challenge in managing the timeline is confronting the silos that exist in most organisations. The fabrication of a product typically spans a series of departments, each which has its manager, workers, budget, and performance metrics. Consequently, people working in different stages may have little to do with each other, even though they have a shared role in creating the same product for the customer. This makes it very difficult to visualise, let alone manage, the value stream as a whole.

Lean companies, therefore, segregate their resources into value streams, each of which represents a product family geared toward a particular type of customer need. Automotive manufacturers, for example, have different value streams for standard and luxury cars. HVAC manufacturers have different value streams for heaters and air-conditioners.

Typically, a value stream manager is responsible for all of the activities in the value stream, and the value stream results. Often, the value stream includes dedicated employees, dedicated equipment, and a dedicated location in the plant.

Case Study – Recreational Trailer Company

A manufacturer of recreational trailers began its Lean transformation in 2009 in the wake of the global financial crisis of the year before. In the initial stages, improvements were being made, but the CEO saw a disconnect between the existing management system and what the company was trying to accomplish on the shop floor. The result of this was a lack of focus on the customer. To address this problem, the company was divided into three value streams:

Value Stream #1: Standard high-quality trailers with little or no customisation.

Value Stream #2: Specialised trailers with a large number of standard options.

Value Stream #3: Custom trailers for customers with very specific needs.

The transformation was remarkably successful. In a three-year period, net income went from virtually zero to 8 per cent, while long-term debt dropped 50 per cent. Inventory turns rose from 5 to 15, and incidents where a fabricator didn’t have the materials to complete a job, dropped from 35 – 40 incidents per week to between 5 and 10 – all this while sales volume tripled.

Principle #2:

Eradication of Waste

The ongoing effort at all levels of the organisation to remove all activities and expenditures that don’t contribute to value that customers are willing to pay for.

As Ohno says in the quote, we reduce the timeline by reducing nonvalue-adding wastes. Accordingly, taking the waste out of value streams is the core improvement activity in Lean environments. Waste removal is effectively the economic engine of Lean because when waste decreases, the value delivered in a value stream proportionally goes up, and the reduction of waste – lower material costs, less space taken up, fewer work hours – all drive costs down, and capacity up.

Waste in a Lean environment is essentially any cost or effort that doesn’t contribute to the value that customers are willing to pay for. For example, let’s say that the raw material for a workpiece arrives at the machining centre. The operator, however, needs another set of dies, so there’s a delay while he or she walks across the plant to get those dies.

The work the operator is doing is necessary, but the workpiece – the proxy for the customer – is kept waiting and doesn’t increase in value during that time. If you were the workpiece, you wouldn’t care why there was a delay – all you would consider is that ABC wasn’t doing anything at the moment to increase your value. The waiting time would therefore be considered waste.

In a Lean environment, that waste might be eliminated by making arrangements so that the operator never has to walk across the plant. Maybe a delivery cart makes the rounds, ensuring that all machinists have all the dies they are going to need during the shift.

There are many other reasons the workpiece might be kept waiting. Maybe the various stages are in different locations in the plant, requiring the workpiece to be transported. Maybe there is a delay in assembly because a parts order didn’t come in. And worst of all, maybe the previous work process was turn out defects, forcing re-work.

Lean improvement, therefore, is about finding ways to improve the processes so that waste can be avoided. Lean companies use the following categories for waste, which were established by Toyota:

1. Overproduction: Producing more than required by the next downstream process, or the customer. Ohno saw this as the “cardinal sin” of waste because essentially it forces all the other wastes.

2. Time on hand (waiting): Workers standing idle awaiting what is required for their next work.

3. Transportation: Excessive movement of the workpiece or parts.

4. Over-Processing: More than the necessary amount of work being done on the workpiece, perhaps due to poor process design or defective tools.

5. Inventory: More finished goods, works in process, parts, or raw materials than required by customer demand.

6. Movement: Unnecessary movements by workers, including bending, straining, and walking to procure tools or parts.

7. Defects: Fabrication of a defective workpiece that will later require correction.

8. Unused brain power: Creative abilities of workers not being utilized to improve process.

Principle #3:

Flow Regulated by Demand

The most efficient arrangement of all value-creating steps in the value stream whereby production is synchronised with customer demand and progresses steadily and continuously.

The idea of flow originated with Henry Ford when he developed the first moving assembly line, that is, the first line where the assembly of a manufactured product literally travelled the length of the plant as it was assembled. Ford found that production is most efficient when the processes are designed in such a way that each takes the same amount of time, so that each workpiece moves steadily through the plant at an even pace.

In practice, flow is very difficult to achieve. As cars got more complex, and there were more and more models to create, even Ford wasn’t able to maintain flow. It wasn’t until the development of the Toyota Production System and the ensuing Lean movement that global manufacturers were able to make real progress at achieving flow.

Flow is sometimes called one-piece flow because in an ideal world, each workpiece moves along the line as if only a single product was being produced – ideal flow conditions mean that there is zero works in progress inventory, and no waiting between stages. Of course, in the real world, even Toyota maintains buffers, but Lean companies keep these to a minimum.

The innovation that made flow achievable was the introduction of the just-in-time principle, which states that all activity must be triggered by demand. This means that you don’t “push” materials onto a production line based on a forecast – you wait for a demand trigger to “pull” production along. In theory, a workstation should never pass product on to the next stage unless “ordered” to do so by the next stage, which is, figuratively speaking, that workstation’s customer.

The command to produce, therefore, initiates with the customer, and moves up the line in the opposite direction to production. This is traditionally established by physical kanban cards or bins, which are passed up the line to notify the upstream provider that more product is needed.

For example, packaging might receive finished goods from assembly in bins. When a bin is empty, this would be sent back to assembly, indicating the need for more product. If there are no outstanding orders and no need (or room) for stock, the bin would not be passed to assembly, and production would stop.

Today, some organisations use electronic kanban systems, which are tied into their financial and production systems, and may be activated by various triggers such as customer orders. How this is accomplished depends on the type of IT systems that are in place.

Principle #4:

First Time Quality

The practice of ensuring that quality is achieved not as an overlay but as an intrinsic element of production, ensuring that problems are solved on-the-spot and as close to the source as possible. The other pillar of the Toyota Production System, in addition to just-in-time, is a principle called jidoka, which is Japanese for “automation with human intelligence”. The idea originated from a feature in an automated loom developed by Sakichi Toyoda, founder of Toyoda Loom Works that evolved into Toyota. The feature was a mechanism that automatically stopped the loom when a thread broke, automatically preventing defective fabric from being woven.

The feature is mimicked by humans in Lean environments in that workers have the authority to stop production if a defect has been found that makes it impossible to complete a step according to quality standards. This is done by pulling a cord, which is called the andon, that activates a visual and audio alarm, alerting supervisors and support personnel.

The practice of dealing with quality problems at the source differs from the traditional approach of sending defects down the line and letting the quality inspectors deal with the problem. Getting things right the first time is ultimately more efficient, and the practice of jidoka is one of the main reasons why Lean companies are so successful at improving quality. However, when Lean was introduced in the West, stopping a production line was considered sacrilege, and it took many years for managers to accept this idea.

An important additional note to this is that safety is managed hand-in-hand with quality. An operator, therefore, will pull the andon if doing the work appears to be unsafe.

Principle #5:

Continuous Improvement

The enlisting and empowerment of the entire workforce to improve their work processes one step at a time following a scientific Plan-Do-Check-Act paradigm.

The big challenge with waste is that it doesn’t show up in major line items that a manager can eradicate with a single initiative, nor does it manifest in big complex problems that can be solved by engineers and other professionals. Waste, for the most part, occurs in hundreds or even thousands of very small increments that are often very hard to see. It therefore takes a keenly trained eye to see waste, and an army of problem solvers to eradicate it.

Toyota employed the idea of kaizen – everyday improvement throughout the organisation – to rally all employees in the cause of fixing problems and raising standards of excellence. Lean companies make significant investments in order to equip and empower front-line employees with the skills and tools they need to remove waste and drive improvement. Often, the improvements are very small, and can be implemented on the spot. For larger problems, more formal methods are used.

A guiding principle for improvements is that they must be based not just on perceptions, but on hard data. The most common method for organising improvement work in a scientific way is the Plan – Do – Check – Act paradigm*. This forces to employee to show reasons for making the change based on real measurements, explain a solution, and test and measure the results.

Lean companies give their employees considerable authority to initiate change at their level of responsibility. The P-D-C-A structure mandates that such initiatives are carried out in a disciplined way, and that accountability is maintained at all times.

Strategy

Mapping Progress in the Value Stream

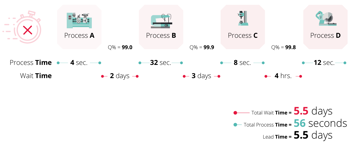

Improving the value stream, that is, shortening the timeline, is typically orchestrated through a strategic planning process called value stream mapping. The process begins with a current state map, which illustrates the performance of the value stream. The map is usually created by a cross-functional team of shop floor workers and managers. Here is a simplified version of a current state map in a typical manufacturing scenario.

This typically shows a timeline at the bottom, which is illustrated by a square wave pattern representing the process time and wait time for each stage. Also shown is the quality coming out of each stage given in percent – 99.9% means that one in one thousand workpieces is defective at that stage.

What most people notice when they see these maps is that the lead time is extremely high when compared with the amount of actual work being done on the workpiece. In fact, the time required for the actual process is a negligible component of the total lead time. This is typical in manufacturing environments, and it is often a shock to managers when they first see these numbers.

There are many reasons for long wait times between stages. Different stages might be in different parts of the plant, so there’s wait time for transport. One of the processes might have a huge backlog that needs to be addressed. Sometimes there are delays because of rework and quality issues. A process might be used for many product lines and have become a bit of a bottleneck. Long setup times can also create long delays between processes.

Whatever the cause, most companies can make significant improvements in lead time, often creating an immediate competitive advantage. It’s not uncommon for a company to improve lead time by 75% or more in a relatively short period of time during the early stages of its Lean transformation.

One of the most common interventions in Lean is moving workstations and equipment so that processes are physically closer together. This might mean de-centralising a function such as welding so that it can be closer to other steps in a particular value stream.

Organising an operation into value streams according to product type, as discussed above, provides the framework for making major configuration changes within value streams to allow more efficient operation. It also ensures better communication between the different stages of production so that they can, as applicable, help each other out.

For example, processes are sometimes redesigned so that there is a better sharing of the workload between the different stages. It may be possible, for example, for Process A to do some additional tasks that would reduce the work, and the time, required at Process B.

Quality is another topic that frequently comes up. As the current state map shows, Process A has a very poor defect rate of 1%, which might be high in that industry, and this might be slowing down Process B. The people at Process A could slow down their process to improve the quality, and because their process takes less time than others, this would not slow down the value stream as a whole.

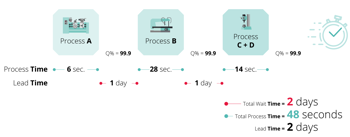

Mapping the future state

Once the planning team has created the current state map, they typically meet again to brainstorm ways to improve the value stream. Quality improvements, re-balancing workloads, or other methods of reducing waste (less transport, removing unnecessary steps) might be discussed. Sometimes, steps are merged – perhaps Process C and Process D could be merged into a single process, removing the wait time between them.

The team then creates what is called a future state map, which illustrates how the value stream could perform if waste is removed and might look like this.

The future state map then becomes a strategic plan where the main improvements are accomplished through a series of projects with specific timelines. These may be led simultaneously by several people who work in the value stream.

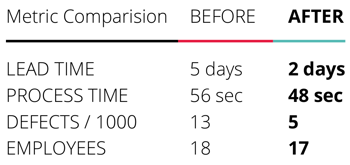

It should be mentioned that the future state map above reflects some very ambitious targets. Here’s a comparison of the “before” and “after” picture:

These improvements are impressive but fairly typical for Lean companies. In fact, the most successful Lean leaders agree that it’s better to have an ambitious goal and fall short than to have a “safe” goal that doesn’t challenge the team. In this example, the difference would be substantial – lower costs, better collaboration, and much faster lead time.

Measuring success at the value stream

In order for Lean to flourish in an organisation, there has to be a wide support for making progress according to basic Lean metrics. These are all designed to guide the company as people in the different value streams work together to reduce waste and maximise customer value. Lean metrics vary by company type, and industry. Here are some of the most common ones used in manufacturing:

Lead Time: This tends to be the master metric at the beginning of a Lean transformation because shorter lead time improves customer service and reduces costs simultaneously. If there is waste in a plant, this will almost certainly affect lead time, so attacking lead time tends to bring waste out into the open.

Direct Costs: Value stream managers focus on actual costs, as opposed to absorption, variances, and standard costs. Numbers they monitor are materials at the actual price paid, labour, factory expenses, depreciation, and facility costs. These are costs that will decrease as improvements are successfully implemented in the value stream. Of course, accounting regulations are followed, but standard accounting reports are not used to guide improvement in the value streams.

On-time delivery percentage: Lean not only shortens lead times but makes production more predictable, and it’s common for Lean companies to deliver to customers when promised nearly 100% of the time. In many environments, being reliable is a competitive advantage, particularly when participating in a supply chain where the customer has tight deadlines to meet.

Inventory turns: As noted above, inventory is considered one of the major wastes in Lean, whether that consists of works in progress (WIP) or finished goods. This inventory turns figure, gross sales divided by the average value of inventory for the year, reflects how well a value stream, or the entire organisation, is doing at reducing inventory to a minimum. It’s typical for a plant starting out with Lean to have only two or three inventory turns in a year. Lean factories can get much higher than that – perhaps twenty or more. Reducing inventory has a positive effect on cash flow. Some classic lean companies, in fact, were able to grow with acquisitions, and fund this completely with cash.

Quality: This is the percentage of defects. Lean companies attack this very aggressively, typically looking for a 50% reduction in defects every year. Since a higher quality rating reduces expensive re-work and avoids product recalls, improved quality has a strong favourable influence on profitability, not to mention improvements in customer satisfaction and market share.

Gross margin: Gross margin is immediately impacted by Lean improvements and is the bottom line as far as the value stream contribution to profitability. In Lean organisations, gross margin is calculated at the value stream level, and is reported as frequently as every week so that the value stream manager can judge the effectiveness of continuous improvement initiatives.

Employee participation: Lean is a continuous improvement strategy, and therefore, depends on a high level of buy-in and active participation. Many senior managers in successful Lean organisations believe that employee engagement is the best leading indicator of success. Leading Lean companies also invest heavily in employees, because they know that employees are the future of the company. This can be measured at the value stream by the percentage of employees who participate in improvement projects. Some organisations are able to get this figure to close to 100%.

Conclusion

These are challenging times for UK manufacturers, and many are finding that doing more with less is not just a strategy, but a requirement for long-term survival. Lean has proven itself repeatedly as the leading methodology for accomplishing this and has helped organisations achieve remarkable turnarounds in virtually every sector of the global economy.

It’s necessary, however, to take a systemic approach to Lean that reflects the interdependency of the various Lean tools and methods and supports wide participation in Lean initiatives at all levels. To support such an enterprise-wide approach, organisations need a solid information framework for tracking performance in all functional areas and making that information readily available to decision makers. This framework is especially critical in the age of Industry 4.0, where an increasing proportion of available data is digital, and where there is a persistent and growing risk of getting overwhelmed with data.

AU & NZ

AU & NZ

SG

SG

MY

MY

US

US

IE

IE