Specialised Engineering Manufacturing Software

Access Manufacturing provides a modular and scalable ERP with functionality-rich modules that can be added to fit the needs of your precision and specialised engineering manufacturing business.

From end-to-end traceability to reducing waste and increasing capacity, our specialist software will help precision and specialised engineering manufacturing companies save money and time, so you can focus on business growth.

Why Choose Access Manufacturing ERP for Specialised Engineering Manufacturing?

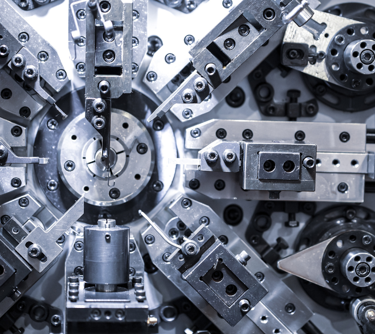

Specialised engineering manufacturers and modern machine shops require clear visibility of machines, employee activity and data in order to optimise capacity, improve cash flow and reduce WIP.

The modular Access Manufacturing Suite includes:

- Shop floor data capture and live dashboards provides an accurate and near real-time full picture of what is happening on the shop floor

- Advanced planning tools to help planners create precise scheduling, with built-in ‘what-if’ analysis

- The ability to check existing stock levels and be flexible on lead times to meet tight delivery deadlines

- Control sales and purchasing orders

- A full audit trail for unbeatable traceability

See our specialised engineering manufacturing software in action

Material Requirements Planning (MRP) For Specialised Engineering Manufacturing

Access FactoryMaster, our MRP software, is used by specialised engineering manufacturing companies to improve cashflow and transform capacity, visibility and traceability.

- Designed to meet the needs of ambitious make-to-order, make-to-stock, and mixed mode manufacturing companies.

- Use the Control Desk feature for rapid creations of suggested purchase and works orders, cancel and reschedule orders directly from your MRP.

- Improved visibility gives you control over your inventory, stock, purchase orders and works orders.

Production Planning Software For Specialised Engineering Manufacturing

Access Orchestrate, our Advanced Planning and Scheduling (APS) software, helps specialised engineering manufacturing companies plan complex production schedules with ease. Generate live plans visible across your team to help identify bottlenecks before they happen and ensure maximum capacity.

- Use the Drag and Drop Gantt Chart to easily allocate machines and resources .

- Plan around scheduled maintenance to ensure minimum downtime and best use of resources.

- Unlock capacity by ‘seeing’ production issues such as bottlenecks more clearly.

- 'What-if' analysis helps planners run scenarios and build accurate models.

- Evaluate multiple production plan scenarios so you and your team can decide on the plan of best fit.

- Provide lead times and delivery dates to customers that are backed by data

Quality Control & Traceability For Specialised Engineering Manufacturing

Our MRP system is built to help specialised and precision engineering manufacturers accurately trace every individual element of a product and show an audit trail at every stage. Access FactoryMaster MRP helps engineering contractors and machine shops maintain excellent quality control.

- Easily identify a non-conforming part, which batch it came from, when it was produced, which product it’s been used in and where it is now.

- Generate reports to support evidence-based decision making for continuous improvement.

- Control non-conformity in materials and components to eliminate defects in the manufacturing process.

- Produce FAIRs (First Article Inspection Reports), demonstrating complete compliance throughout.

- Quarantine faulty or damaged parts and keep audit trails so items can be scrapped or reworked.

- ‘Quality Tree’ feature helps you keep all your certificates of conformity and associated quality documents in one place, against the finished batch.

Customer Success Story – Micro Mesh Engineering Ltd

Founded in 1968, Micro Mesh Engineering Ltd produce high quality hydraulic and air filtration systems. They have been using Access FactoryMaster MRP for over 15 years, seeing vast improvements within 3 months of implementation.

Watch our video interview with James Underwood, Managing Director at Micro Mesh Engineering Ltd to find out how Access FactoryMaster transformed their engineering manufacturing operations.

We saw vast improvements within 3 months

- James Underwood, Managing Director at Micro-Mesh Engineering Ltd

Enhanced Security For Specialised Engineering Manufacturing Software

Our ERP systems depend on data, and it is our priority to protect your sensitive data and systems. Our software is cloud-based and robustly protected from cyberattacks. Our data centres are in 7 locations on 4 continents. Each location is ISO27001/SSAE-16 certified and highly optimised for cloud computing.

Our security features include:

- Cloud Backup and Disaster Recovery

- Fully automated application-level testing and failover

- Automated backup and recovery testing

- Automated Disaster Recovery compliance reports

- Recovery Assurance for local, second site and cloud