What is Procurement in Construction? (And What Are The Best Methods?)

Every construction project begins with the procurement and coordination of goods and services.

In this article, we look at methods of procurement in construction, procurement contracts, framework agreements and much more.

Contents

- What Is Procurement In Construction?

- What is a framework agreement in construction procurement?

- What are procurement contracts in construction?

- What are the different methods of procurement in construction?

- Which procurement method should I use in construction?

- How can ERP transform your procurement process?

What Is Procurement In Construction?

Procurement in construction refers to the crucial process of acquiring the necessary goods and services to successfully accomplish a construction project. It involves meticulously selecting the most suitable contractual arrangement, inviting tenders, and finalising the essential contracts needed to initiate the project. Additionally, procurement in construction often encompasses securing the required funding facilities to ensure smooth project execution.

Because of the many various professionals involved in a project - surveyors, designers, architects, suppliers and more - a clear procurement strategy is critical to a successful project.

Effective procurement will ensure that all the necessary materials and services are available to complete a project on time, within budget and to the required quality standards.

Selecting the right procurement route for a project can encourage long-term relationships and help mitigate risk by putting contractual protections in place.

There are many different procurement routes to choose from, so it is important to consider long-term business goals when selecting a procurement strategy.

What is a framework agreement in construction procurement?

Often clients that regularly commission construction work will put a framework agreement in place before making a contract.

A framework agreement should define the scope and locations of works and services needed over a period of time. It is an agreement between a client and suppliers, establishing the terms of governing contracts that may be awarded over a set amount of time.

A framework agreement can save a client time on pre-qualification processes when a specific project becomes available, they are able to select one of the suppliers under the framework agreement to start work.

Another benefit of a framework agreement is building strong supplier relationships, as you become familiar with how people like to work and communicate.

Framework documents should describe the contract conditions setting out the allocation of price and risk between client and supplier.

What are procurement contracts in construction?

A procurement contract outlines the pricing mechanism that will be used depending on the amount of risk both the client and supplier are willing to take.

There are many types of contracts and structures that might be used determined by the size and complexity of a project.

There are many types of procurement contracts used in the construction industry, some of the most used being:

Lump sum contract

Lump sum is the most common form of construction contract.

Under this type of contract, a single 'lump sum' price is agreed before construction works begin. Often a lump sum contract can be confused with a fixed price because of there being more certainty over the final cost.

Lump sum contracts are not fixed, the price may change under circumstances such as design variations, bad weather, inflation fluctuations and statutory fees. If the cost exceeds the agreed price the contractor will pay additional expense or if the cost is less the contractor will benefit from savings.

Cost reimbursable contract

Cost reimbursable contracts are sometimes referred to as cost plus. For this contract, the contractor is reimbursed all the costs incurred when carrying out the works, plus an additional fee.

This type of contract tends to be used when the scope of a project is not easily defined and there are high risks involved, for example, emergency reconstruction work in the case of a fire. This carries high risk for the client as the cost is not known at the start and finalising the costs may be a complex process.

The client will often monitor construction site activities to check that the costs being charged are legitimate and that the contractor is operating efficiently.

Guaranteed max price contract

With this type of contract, there is an agreement between the client and contractor that the cost will not exceed a specified maximum. If the cost goes above the agreed price the contractor is responsible for paying the added costs.

This gives the client the security of a price cap whilst incentivising the contractor to make savings. The risk in this type of contract falls onto the contractor, for example, bad weather or complex groundworks may incur unexpected high costs.

This often results in contractors tendering a high price to account for risks.

Streamline construction procurement with Access Coins ERP

Access Coins is a leading ERP software for construction built to help streamline the procurement process.

What are the procurement methods in construction?

A procurement method is the route in which both the design and construction work is procured. The method chosen should align with the client's long-term business goals.

There are many different procurement methods to choose from with influencing factors of speed, cost, quality, and risk to consider. The main procurement methods in construction are:

Traditional procurement

The traditional route, often referred to as 'design-bid-build' is the most commonly used procurement method in construction. The client will appoint a consultant to design the project and prepare all tender documentation, such as drawings and bill of quantities.

Contractors will submit tenders based on these documents and the client will choose a contractor from these submissions. The contractor is responsible only for building works with limited influence over design cost and risk allocation.

The traditional procurement method will typically use lump sum contracts with penalties for delays in project completion. It is seen as a fairly low risk route for a client as the contractor will take on the financial risk, provided that the initial design information given to the contractor is accurate and complete.

Separating design and construction can have its downsides, the fragmented nature of this method may cause competition and disputes between the teams. A lack of collaboration often leads to data omissions or mistakes, and rework, if the right processes and technology are not in place.

Design & build procurement

This method has increased in popularity, a recent survey published by Ryder Levett Bucknall claims it is now the most used method. With this procurement route the contractor has responsibility for the design and the construction works. A client will give contractors their requirements for a project and contractors will submit a proposal including a price for the works. A contractor can use in-house designers or work with a consultant. This method often appeals to clients as it gives them one point of contact throughout, avoiding having to be the go-between for different teams.

Design and build procurement contracts are usually on a lump sum basis. It is a low-risk method for clients as they have no responsibility for design and a price is decided upon early in the project. However, early price certainty is dependent on there not being expensive variations to the original brief.

Partnering/alliancing procurement

Partnering is sometimes referred to as alliancing or a joint venture. This method is a collaborative approach enabling full integration of design, contractors and suppliers and spreads responsibility across multiple parties.

All contributing parties share the risk and rewards associated with a project. This method can be used for a one-off project but often reaps the greatest benefits over longer-term arrangements as there is more opportunity for building relationships and improving the way everyone works together.

For this procurement route to work effectively there needs to be a shared goal throughout with established collective incentive schemes. It is crucial that the partners chosen have aligning cultures and collaborative mindsets to break down traditional barriers that exist within the construction industry.

Contracts are often cost reimbursable with both collective and individual incentives and penalties outlined. Problem resolution is an important aspect of this method for the client, they must play the part of adjudicator of disputes.

Any disputes that arise need to be carefully dealt with a solution-based remedy rather than appointing blame. This ensures the culture of trust is not broken and the project is continuously improving. Partnering requires the adoption of effective collaborative measures and a constant feedback loop.

Management contract

For management contracts, the client will appoint a management contractor to choose and manage the works contractors needed for a project. The appointed contractor will typically not carry out the work but instead manage several different contractors. The client will appoint a separate design team giving them high input into the design.

With this method, construction works can begin before the design is complete, giving a level of price uncertainty due to potential adjustments during the project. The management contractor is usually on a cost plus arrangement. The client will reimburse the management contractor for the amount paid to their works contractors and is paid either an additional percentage fee or fixed fee.

Construction management

Construction management is a procurement method where the construction works are carried out by a number of different trade contractors. The client will have direct contracts with all the trade contractors, but they are managed by a construction manager. Similar to the management contracting process but the client is contracted to the trade contractors instead of the main contractor.

Appointing a construction manager allows some trade packages to start work before the design is complete, for example, piling. This is a fairly high-risk method for clients as they will have a lot of consultants and contractors to deal with and there is a level of price uncertainty.

How to choose a procurement method in construction?

When selecting a procurement method in construction, it's crucial to consider several factors to ensure the success of your project. Start by evaluating your project's scope, budget, timeline, and complexity. Next, assess the level of risk you're willing to take and the desired level of control over the construction process. Additionally, consider the specific project requirements, such as design flexibility, collaboration needs, and stakeholder involvement. Finally, weigh the pros and cons of various procurement methods, such as traditional design-bid-build, design-build, construction management at risk, or public-private partnerships. By carefully analysing these factors, you can make an informed decision and choose the most suitable procurement method that aligns with your project goals and maximizes project outcomes.

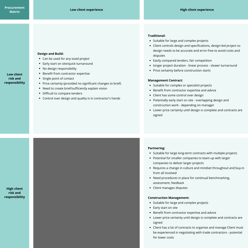

To help with the decision, here is a procurement method matrix:

How can ERP transform your procurement process?

Using an ERP (enterprise resource planning) system within a construction business can streamline the procurement process in multiple ways. It can standardise Requests for Quotation (RFQs), automate purchase orders, centralise supplier management and improve visibility across the entire chain. ERP provides one source of truth for your company’s data, ensuring that procurement team members are always working from the same page.

A real-time view of procurement data leads to a far more efficient procurement process, combined with reduced costs.

More construction software information, guidance and advice